Little knowledge of hydraulic system

A complete hydraulic system is generally composed of power components, actuating components, control components, auxiliary components and working media.

1. A complete hydraulic system is generally composed of power components, actuating components, control components, auxiliary components and working media. The power component is a hydraulic pump; The actuating element is a cylinder or a motor; The control elements are various valves; Auxiliary components are various pipes, oil tanks, etc; The working medium is hydraulic oil. At present, the hydraulic pump station integrates power components, control components and some auxiliary components.

2. Hydraulic pump station can be divided into valve control system and pump control system. In the valve control system, the output flow and output pressure of the hydraulic pump are fixed. The flow and pressure required by the user are achieved by adjusting various valves, such as proportional valve, throttle valve, etc; The proportional valve regulates the output pressure, and the throttle valve regulates the output flow; Proportional valve is an overflow valve that can adjust the pressure steplessly. At present, there are two categories of manual proportional valve and electromagnetic proportional valve. The pump control system regulates the whole system by changing the output flow of the pump, and variable displacement pump is required. However, the pressure still needs to be adjusted by the proportional valve.

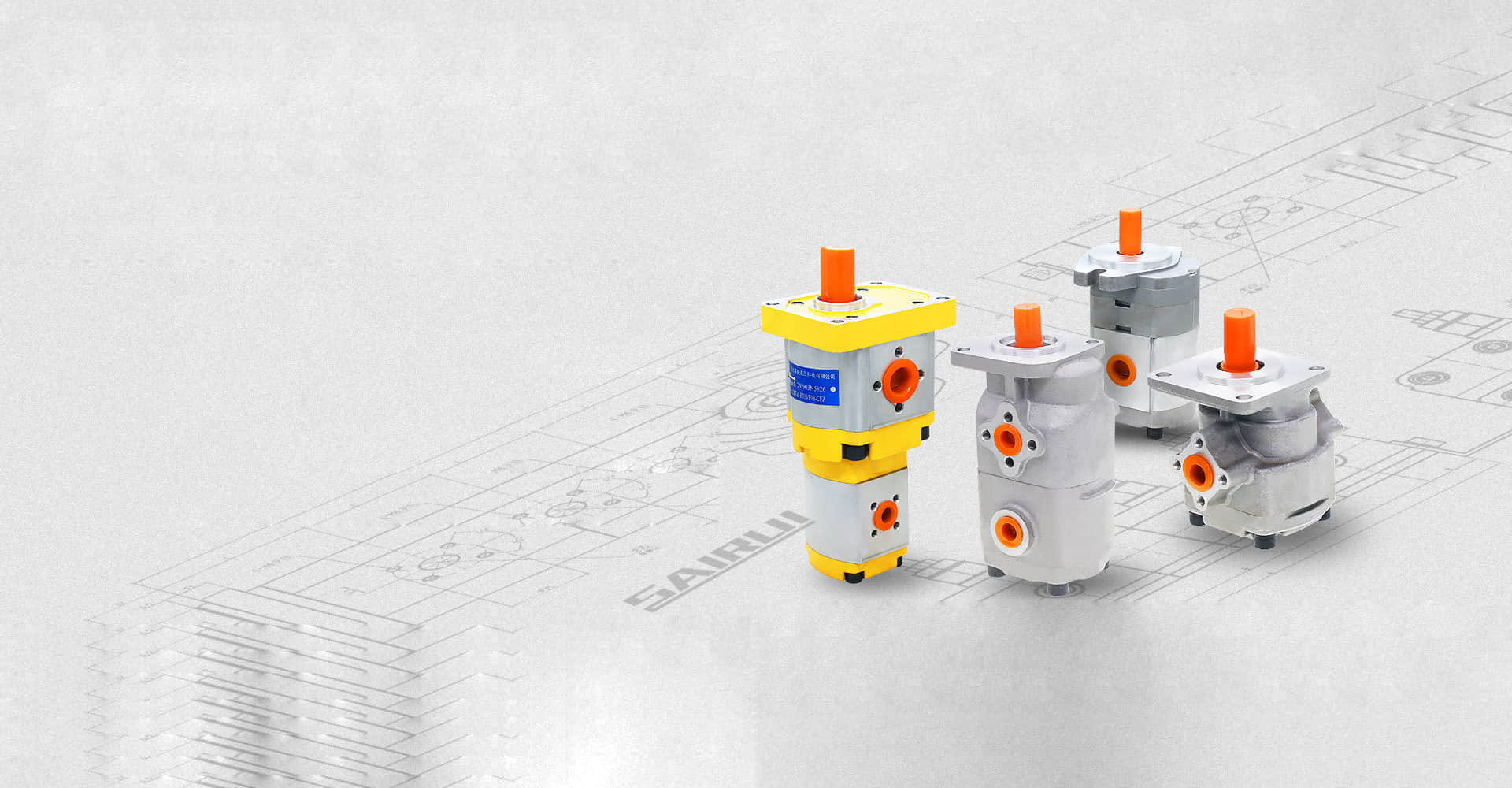

3. Hydraulic pump can be divided into gear pump, vane pump and plunger pump; The gear pump is a constant displacement pump, and the output pressure and flow are a fixed value; Vane pump and plunger pump are divided into fixed displacement pump and variable displacement pump. The output pressure of variable displacement pump is certain, but the output flow can be manually adjusted; Gear pump is a system formed by the mutual motion of a group of meshing gears; Gear pump is divided into external gear pump and internal gear pump. The gear pump can output a pressure of more than 30MPA.

4. The service life of external gear pump is short and the noise is high. At present, a pump can only be used for more than a year and needs to be replaced; The relative life of internal gear pump is longer, and its biggest advantage is low noise. At present, the noise of internal gear pump produced by many manufacturers on the market can be controlled at about 50 dB at 1500 rpm; At present, most of the electro-hydraulic servo systems use internal gear pumps.

5. The external gear pump is a common gear pump at present, and it is also more popular in the domestic market at present; Vane pump can be regarded as centrifugal pump; Vane pump is divided into single acting variable displacement pump and double acting constant displacement pump. At present, the maximum output pressure of domestic single acting variable displacement pump is about 7MPa. For imported double acting constant displacement pump, the high pressure pin vane pump can reach more than 30MPa. The vane pump is more expensive than the gear pump. The output flow of a single acting variable displacement pump is changed by adjusting the eccentricity of the impeller.

6. The gear pump and vane pump have a phenomenon of internal leakage and oil trapping.

Because when the pump works, the oil in the oil suction area is always low pressure and the oil in the oil outlet area is high pressure. Then there is a tendency for the oil in the high pressure area to flow to the oil in the low pressure area. Because there is always a gap between the teeth, there must be a tendency for this flow. That is to say, there must also be this flow. This tendency for the oil in the high pressure area to flow to the oil in the low pressure area inside the pump is called internal leakage.