Technical problems in application of triple gear oil pump

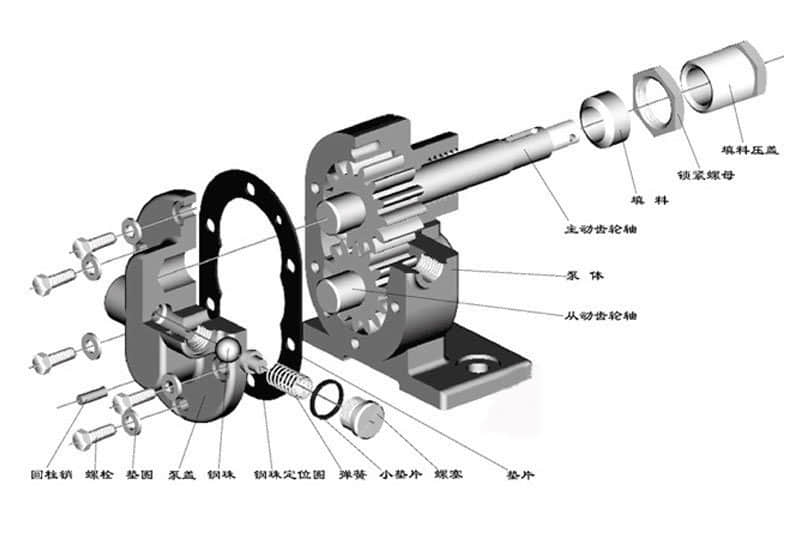

The pressure relief of the shaft sleeve is beneficial to remove the dead volume generated during gear engagement, so pay attention to the pressure relief position during assembly.

Technical requirements for assembly of triple gear oil pump:

1. During assembly, the mating surface and friction surface of each fitting shall be coated with engine oil, and the self tightening oil shall be sealed in the oil pump cover to the bottom without damaging the sealing table.

2. Clean the whole accessories with gasoline or diesel, and carefully check the technical status of each accessory. During assembly, the width of driving gear and driven gear shall be the same to ensure that the gear end face and shaft sleeve end face fit tightly during oil pump operation; When the sleeve gear is assembled into the housing, the axial clearance of 0.10-0.12mm shall be guaranteed; The small sealing ring shall be higher than the ring.

3. The pressure relief of the shaft sleeve is beneficial to remove the dead volume generated during gear engagement, so pay attention to the pressure relief position during assembly. The pressure relief plate and seal ring shall be at the side of the oil suction chamber, that is, the side of the large hole with the word "inlet" on the oil pump housing.

4. When screwing the screws from the pump cover to the housing, it should be rotated alternately several times with a torque of 49~59N · m.

5. When the assembled triple gear oil pump rotates the driving gear by hand, it shall be smooth and free of belt clamping, and the rotating torque shall not be greater than 3N · m.

2、 When disassembling the gear pump, pay attention to the following issues:

1. The gear pump is a precision part. When it is not judged that the fault really occurs in the gear pump, it should not be disassembled easily.

2. After removing the gear pump assembly, clean the oil dirt and dust outside the oil pump assembly. Before disassembly, a mark shall be made on the pump cover and pump body with a steel sheet (using a marking pen as far as possible) for assembly according to the mark.

3. Parts that are seriously worn and can no longer be used shall be replaced with new ones in sets or pairs. If a pair of gears should be replaced, otherwise the difference in the gear engagement between the two gears will affect the oil delivery pressure.

4. The disassembly of the triple gear oil pump shall be carried out in a clean place. After the removed accessories are cleaned with gasoline or diesel, carefully check the wear condition of each accessory to confirm whether it can continue to be used, and then carefully place the accessories that can continue to be used in order.