Tips on maintenance of gear pump

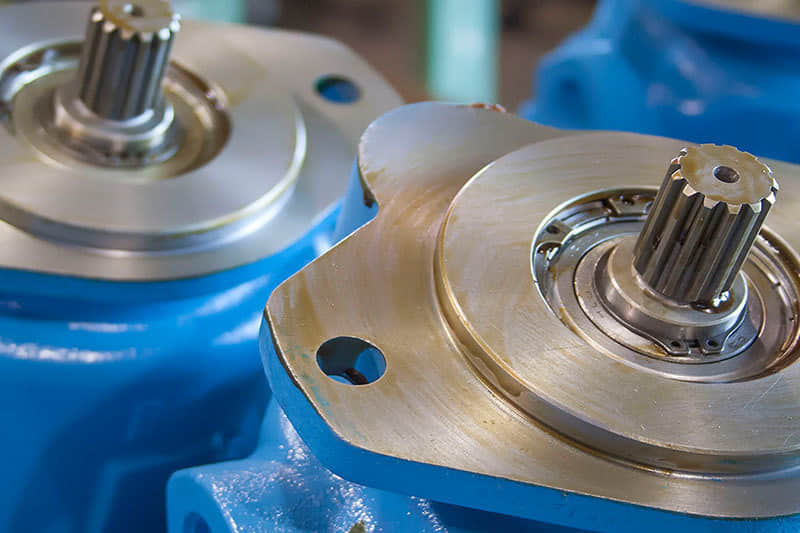

"When the drive shaft and bushing are worn, the clearance between the drive shaft and bushing increases, and the pump oil volume must be affected. "Under the circumstances, it can be used to repair the normal working clearance of the drive shaft or bushing. If the drive shaft is worn and the indicator light is on, just press the old bushing to replace the lining with standard specifications, and the clearance can be restored to the allowable category. If the severity of the drive shaft and bushing is serious, and the severity of the matching clearance exceeds the standard, not only the bushing should be replaced, but also the drive shaft should be chrome plated or vibration surfacing to increase the diameter of the bushing And then reach the specification, and the mutual fit between the repair and the bushing is fixed.

Secondly, repair the cracks in the lubricating oil pump housing repaired in the house:

The shell crack can be repaired by welding with 508 nickel copper electrode. The welds are tight, forming air holes, and the flatness deviation of the joint surface with the pump cover is not greater than 0.05mm.

Grinding and repair of drive shaft bushing hole and driven shaft hole: After the shaft bushing hole is worn, wear marks can be removed by reaming, and bushings of corresponding specifications can be used. Wear the driven shaft hole, remove the wear mark with the reaming method, and then adjust the driven shaft according to the actual specification of the reamed hole.

Repair the inner cavity of the pump casing: wear the inner part of the pump casing. Usually, the lumen window is repaired by lining the large inner cavity with cast iron or steel. After the window sash, the inner cavity is lined to the predetermined size, and the protruding end surface of the wear sleeve is connected with the pump housing so that it is flush with the surface.