What is the use of the bearing on the hydraulic gear pump?

The substrate of DU bearing is low carbon cold-rolled steel plate, the middle layer is sintered spherical bronze powder, and the friction surface layer is rolled modified PTFE.

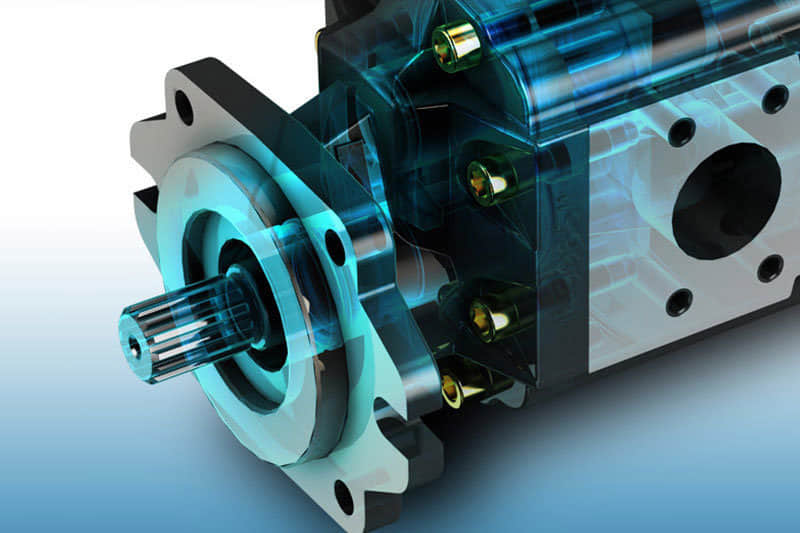

At present, needle roller bearings widely used in hydraulic gear pumps have many advantages: high load capacity; The friction coefficient is small, the friction force is small when starting and working, and the mechanical efficiency is quite high; It can be applied to high and low speed at the same time; It can be applied to a large temperature range; Strong oil pollution resistance.

But at the same time, there are many disadvantages: high noise, large overall dimensions, and inconvenient overall structure layout; Especially in the hydraulic gear pump, long needle bearing is required, which leads to the sensitivity of bearing performance to manufacturing and assembly accuracy, high requirements for needle accuracy, and strict requirements for heat treatment process procedures; At present, this kind of wave needle bearing is a non-standard part, which requires special customization and has high cost.

In recent years, with the gradual improvement and maturity of the research, development and manufacturing technology of DU bearings in China, their bearing capacity and service life have increased correspondingly, while the price has also decreased rapidly, and their applications have become more and more extensive. Generally, the allowable specific pressure of DU bearing can be stabilized at 34MPa. If the structure is reasonable and enough lubrication is ensured, the allowable specific pressure can be stabilized at 44MPa, and the maximum specific pressure of bearing can reach 58MPa.

The substrate of DU bearing is low carbon cold-rolled steel plate, the middle layer is sintered spherical bronze powder, and the friction surface layer is rolled modified PTFE. The wall thickness of shaft sleeve is 0.7~2.5mm, and the thickness of friction surface layer is 0.02-0.06mm. Tin plating and copper plating can be selected for steel back anti-corrosion.

The bearing can work without lubrication, with small resistance, wear resistance and long service life. It is more suitable for the specific complex working conditions of gear oil pump bearing. The thin wall structure has the advantages of compact structure, light weight and small volume, and makes the structure of the gear oil pump more reasonable and the structure design convenient. For example, the size of the gear journal can be increased to increase the overall strength and rigidity of the gear shaft.

After the hydraulic gear pump adopts DU bearing, the purpose of increasing the rated pressure of the gear oil pump, reducing noise, increasing impact resistance and increasing service life is achieved.